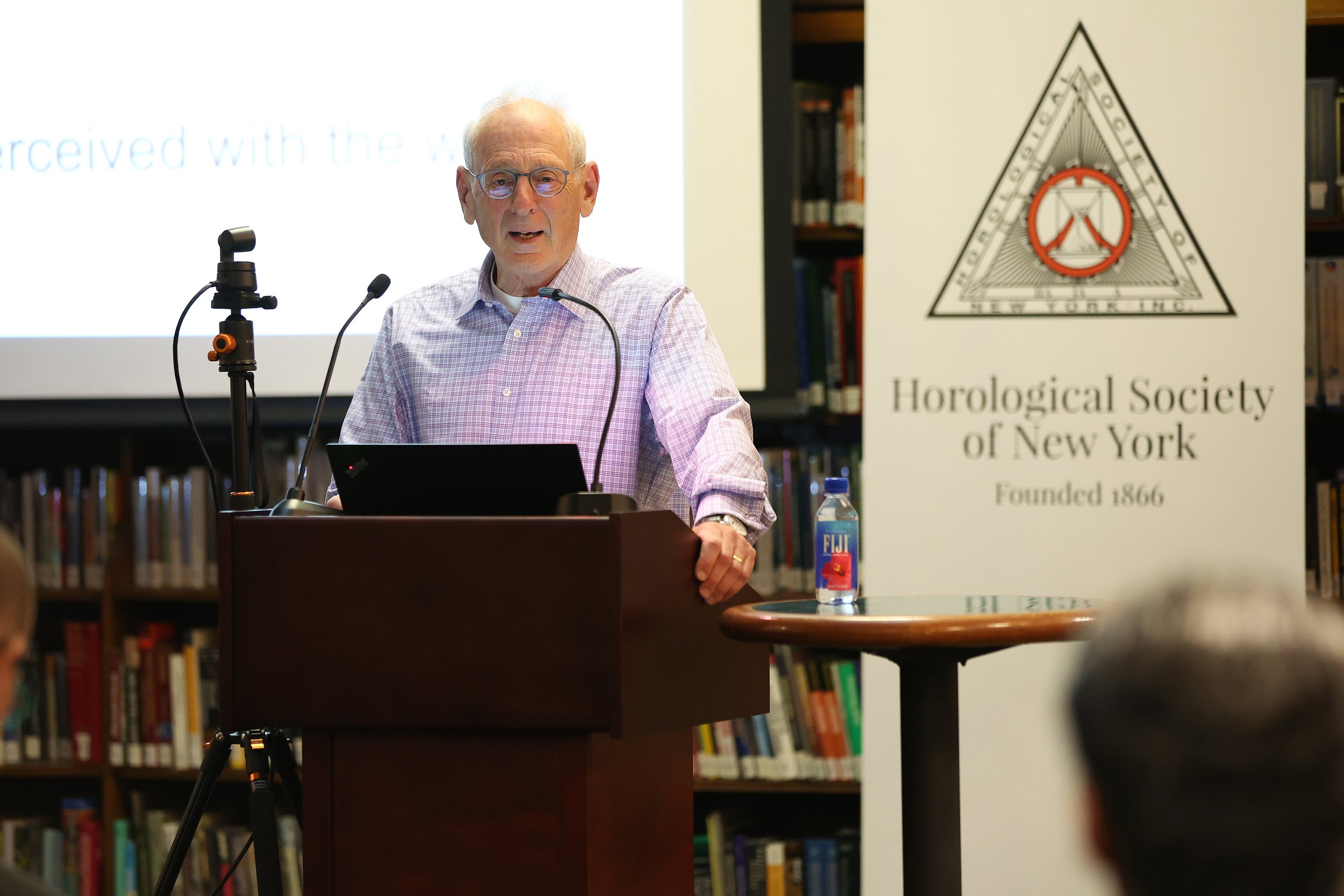

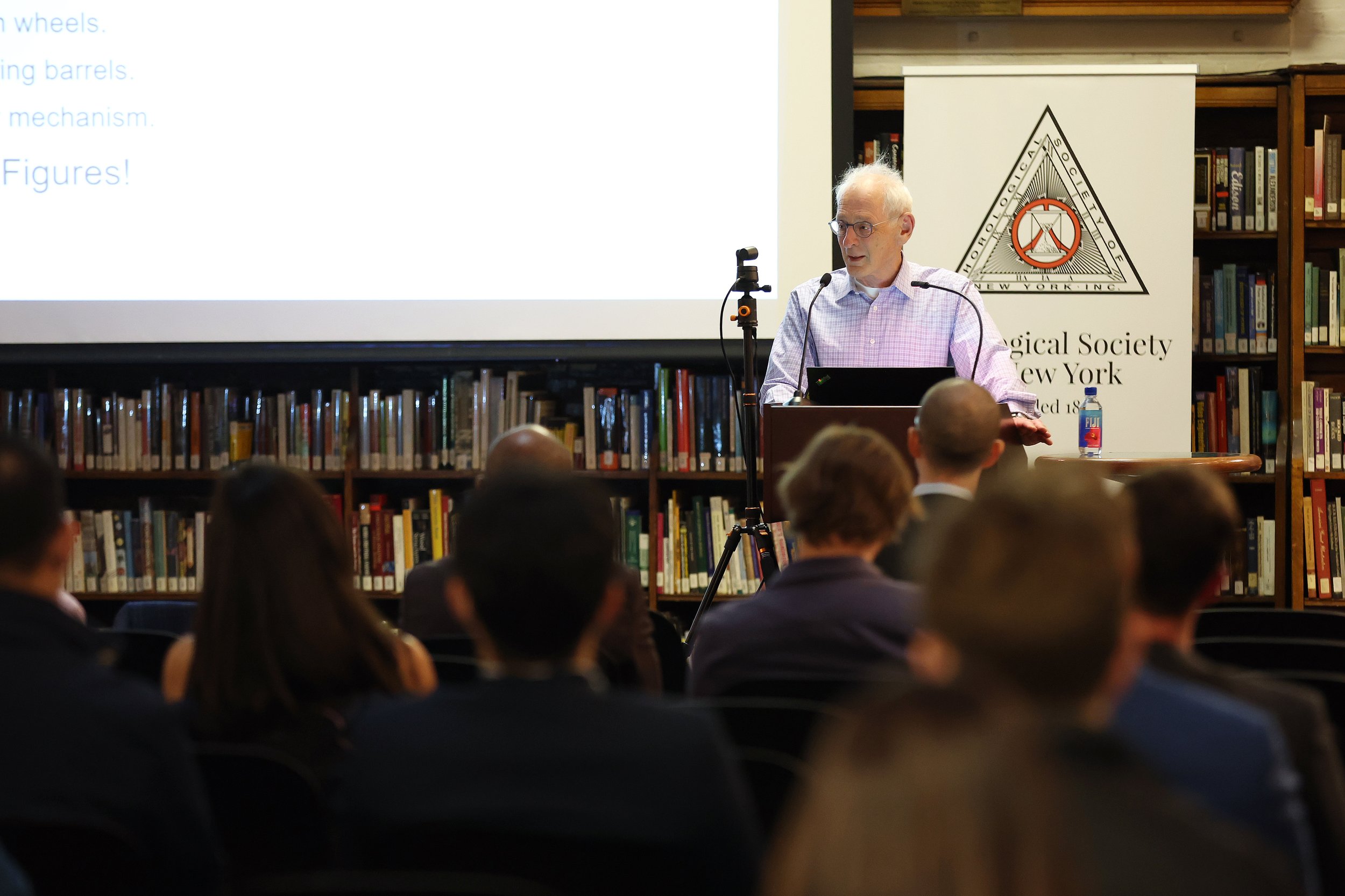

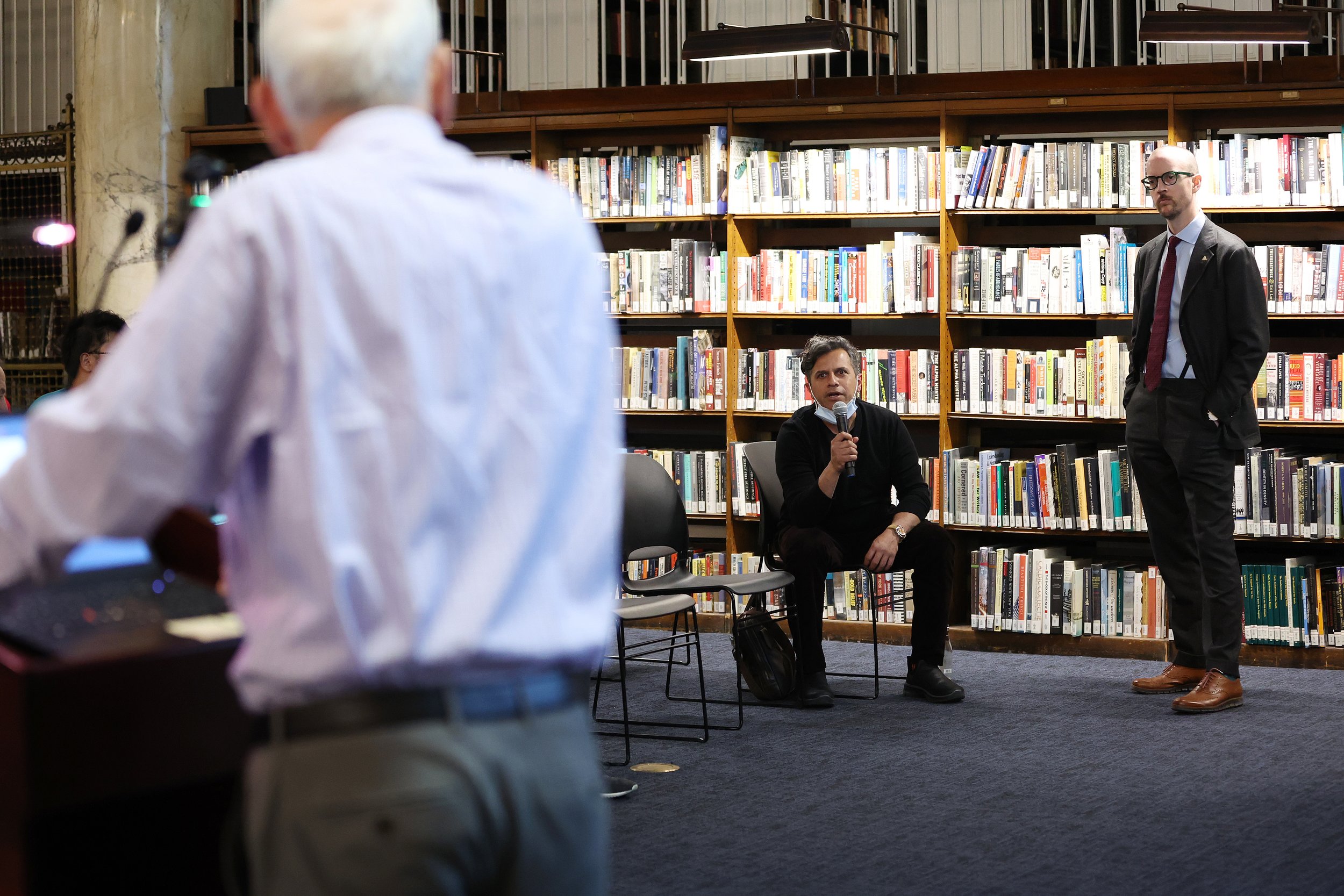

Meeting Recap: Hidden Figures: Overlooked Elements of Watchmaking

Jeffrey Kingston, Editor-in-Chief of Le Quai de l’Horloge (Sun Valley, Idaho)

May 5, 2022

Video recordings of lectures are available to members immediately (using your membership password), and to the general public with a two-month delay.

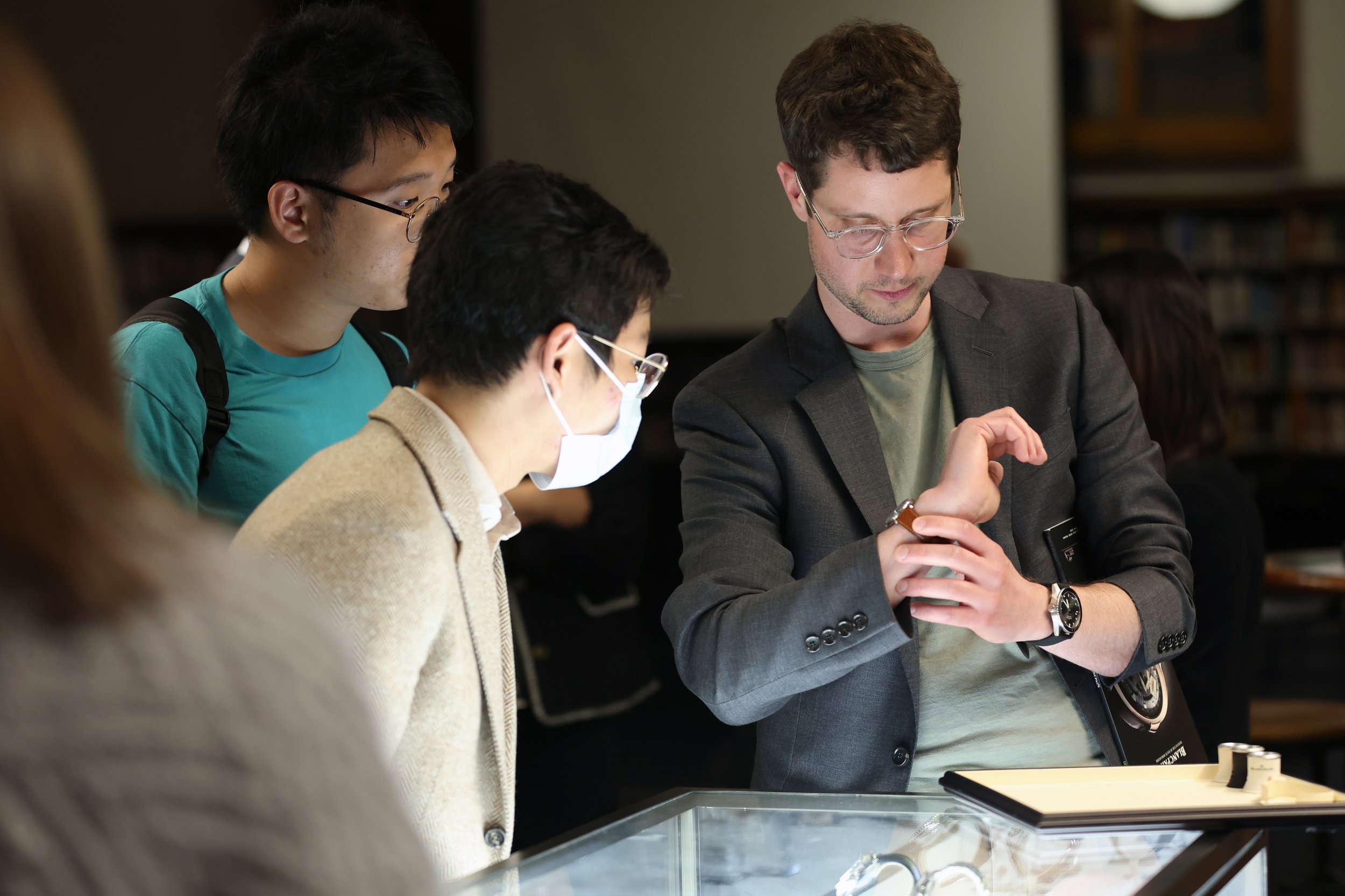

For the May 2022 lecture at the Horological Society of New York (HSNY), Jeffrey Kingston talked about the overlooked mechanisms of a timepiece. Watch enthusiasts often admire a particular complication, a certain feature, finishing embellishments, thinness, and sometimes the allure of scarcity. These aspects are immediately seen.

However, Kingston pointed out five areas he believes are the ‘hidden figures’ within a watch: inertial regulation, silicon hairsprings, copper beryllium wheels, multiple mainspring barrels and secure calendar mechanisms. So what is tested to establish the value of a ‘hidden figure’? According to Kingston, it needs to deliver value and make the watch better without bringing attention to itself.

Inertial Regulation

The advantage of this type of regulation (as opposed to the raquette regulation) is that the trial-and-error component is significantly reduced. There’s improved robustness, shock resistance and stability.

Silicon Hairsprings

If the adoption of silicon hairsprings is compatible with traditional watchmaking, then the material more or less preserves the tradition. The advantage is the extraordinary resistance to magnetism, the lighter weight, its idealized shape, its uniform response to impulses and that it ages more slowly than metallic alloys.

Copper Beryllium Wheels

The three main materials of choice for wheels are brass (90% of the industry uses this material), German silver (an alloy of mostly copper and zinc though rarely used) and copper beryllium, which turns out to be the most expensive of the materials. Its advantages are lower friction and greater hardness which results in better wear properties. With copper beryllium, the material can be stamped with a precision of less than 3 microns. Therefore, the greater the precision of the watch part, the better the watch will perform when utilizing copper beryllium wheels.

Multiple Mainspring Barrels

These aid with longer power reserves and are connected in a series. Due to the stiff, strong spring in the outer barrel and the thick spring of the inner barrel, they calibrate the strength of the springs to optimally replenish the innermost barrel. The effect is to get a relatively flat power curve of time.

Secure Calendar Mechanisms

The problem with most complicated calendar constructions is the risk of breakage when manually setting the timepiece during the automatic date changes. Having a secure mechanism within the calendar complication will maintain the integrity of the day of the week, date and month.

HSNY thanks Jeffrey Kingston for his fascinating lecture!

Submitted by Melody Benloss, Recording Secretary

Photography by Monica Schipper